You could take a college course to learn some of the skills you'll need in this job.

Relevant subjects include:

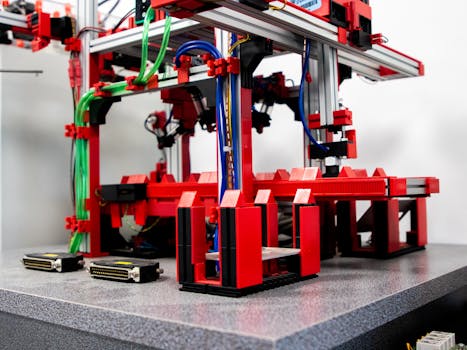

- engineering

- mechanical or electrical engineering

- fabrication and welding

- T Level in Maintenance, Installation and Repair for Engineering and Manufacturing

Entry requirements

Entry requirements for these courses vary.

4 or 5 GCSEs at grades 9 to 4 (A* to C), or equivalent, including English and maths for a T Level